What about Fire?

Impact of fire on a Log Home,

You may love the idea of having your own custom log home but are leery to decide based on the possibility that a house built solely of wood will therefore burn faster then a conventional or framed style house. The answer is no, and below I will provide some links to take you to various studies and groups around the country to show why Log homes are actually safer in a fire then a conventionally framed building.

These links will open in a new window.

Fire Performance of Log Walls , go to the Library on this website and follow the link.

ILBA Article , Lots of info on this site under resources, documents.

Fire, Heat & Log Homes

By Robèrt Savignac

Featured in: ILBA Log Building News #43, May/June 2003

In a recent presentation to an insurance association, it came to no surprise that their general understanding of log homes is shouldered with the insurance industry’s preconceived notions of the combustibility and high risk potential of living in a log home. While wood certainly does burn, the ILBA has no shortage of specific research and data relating to the fire resistance and thermal performance of log homes.

The group of insurers and assessors were able to douse their fears. Examples of numerous homes that have “burnt” and were then restored and re-occupied lent to some of the greater advantages to building with logs, when compared to the insurance fire risk of “conventional” construction using stick and steel components.

By illustration a case history was presented of a log home of 10-12” diameter logs that burnt for 30 hours of flames. After the smoke cleared all the log walls were still intact and in place. The logs were sandblasted, re-coated to remove the lingering smell of smoke, and the building rebuilt anew.

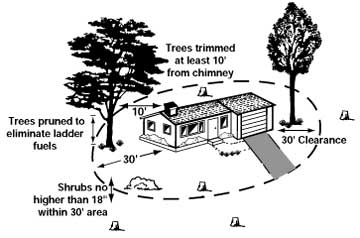

Log home insurance premiums are high not necessarily due to the logs themselves, but more so due to their locations (distant from fire suppression services) and several other factors, including occupancy profile, where log home owners are more prone to burning wood as either a primary or secondary heat source or simply for entertainment in a fireplace. There is a higher occurrence of wood stoves and fireplaces in log homes compared to stick houses.

All things being equal, it was demonstrated that homeowners are safer in log homes compared to the limited “life” of a burning stick house. According to the National Fire Protection Association, “most building fires are started by heat sources and ignitable materials that are brought into the building, not built into it.” In fact, the layer of char that develops on a log surface during its burn helps to protect the wood and maintain its strength and structural integrity.

By Mark Fritch

Featured in: ILBA Log Building News #34, June 2001

Based on: ILBA conference presentation by Dalibor Houdek, Fornitek Canada Corporation

Dalibor began his presentation by saying, “First, wood doesn’t burn; it is a good insulator.” He clarified that as heat is applied there is thermal degradation that causes wood to give off gases, and it is the gases that are flammable.

Dalibor, working on his PhD at the Technical University of Zvolen, Slovakia, built a furnace that applied heat to one side of 11-inch diameter scribe-fit logs, in which the long grooves averaged 50 mm (2”) wide. The logs were kiln-dried spruce at 19% moisture content.

Fire resistance is defined as the ability of a wall system to withstand exposure to high temperatures without collapse – and so a vertical load was applied to the top of the test walls.

The walls were equipped with thermocouples and monitored as heat was applied to one side – the ISO 384 standard test. For 45 minutes heat was applied to one side – and it reached 700º C (1,300º F). No flames penetrated the wall during the test, and there was no structural failure.

The thermocouples showed there was no measurable increase in temperature on the side of the wall opposite the furnace. In fact, once the heat source was removed, the log walls stopped burning on their own in just two minutes.

Dalibor then showed a dramatic video of the large-scale burn test. A scribe-fit wall panel about 8-feet square was built, and a heat source applied flame to one side of the wall. The wall was preloaded with a fixed load and rigged with thermocouples.

After three hours there was no penetration of flames through the wall. The temperature on the side with the furnace was 1,100º C (2,000º F), and the highest temperature reached on the other side was just 32º C (90º F).